Marine engines proactive maintenance

- by Rares Badrea

-

in Blog

-

Hits: 4544

According to studies performed by one of the most reputable marine engine manufacturers, around 75% of engine repair work can be directly or indirectly attributed to lack of proper care for the engine and this is especially true for the care (or lack of) during the off-season. Without proper off-season storage procedures applied at the end of your season, there is no way on Earth for a mechanical engine to be sitting idle for say six months or more and then be ready for instant, satisfactory service. Just try to leave your car sitting for that long and then one morning just expect to start, run as usual and go to work… You will be taking the bus that day!

There are so many things that can go wrong in a car sitting for that long and twice as much for a boat. Just to mention a few, the battery will go dead flat, the fuel will lower the octane rating to the point that upon restart will damage your engine, the moisture left in the engine could potentially seize it and the list can go on.

Therefore even in mild winter conditions like Australia, the engine (if was not properly stored for off-season) has to be run at least on flusher once a month. Start engine and run to operating temperature (5 to 10 min) and this way you will also put a fresh charge into the battery. With the engine running select forward and reverse few times. Observe gauges for proper operation because corrosion can occur in the wiring and cause erratic or no readings at all. Stop the engine and operate the trim up and down, steering port to starboard. If the boat is on a trailer is a good idea to check the pressure on your tires and move the trailer forward and back a few meters to give the wheel bearings a run as well.

Only through a regular maintenance program can the owner expect to receive long life and satisfactory performance at minimum cost. Many times, if an engine is not performing well, the owner will “nurse” it through the season with genuine intentions of working on the unit once it is no longer used. Yes, because it is full season and we use the boat with family and friends and we have a lot of fun… Until we break down in the middle of all this fun and the living dream becomes a nightmare! And most of the times a very expensive one! Can it be prevented? OF COURSE! How? By proactive maintenance all the time!

As with many New Year’s resolutions, the good intentions to look after the boat are not completed and it may lie for many months before the works begun or it is taken to a marine shop for repair. Let’s imagine, if you will, that the engine you have is a 2 stroke and the cause of the problem is a blown head gasket. As with any blown gaskets, most of the time the water finds its way into the cylinder(s). Worst case scenario: salt water! This water, allowed to remain over a long period of time, will do considerably more damage than it would have if the gasket had been replaced immediately. Another example, now for a 4 stroke fuel injected engine. EFI 4 strokes are equipped with a VST (vapor separator tank) where fuel is pumped in and cooled in order to be vapor free prior to be pressurized in your injectors by the high pressure pump (located as well in the VST). As fuel can contain water to around 15% in emulsified state, if that fuel is left in the VST for long periods of time, the water will eventually separate from fuel at the bottom of the VST and will corrode and block internal parts of the pump. As a result the fuel will not be pumped at the right pressure and your engine will run poorly if at all.

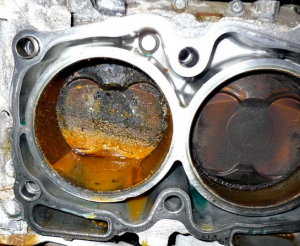

Here is an example of salt water damage for an engine with a blown head gasket. The owner put the boat in storage for 3 months prior to repair. Because of that the repair was 4 times more expensive.

Another example with a carburetor left with water contaminated fuel during the off season.

This are just a few of the many possible scenarios that can lead to expensive repairs. In the following series of articles we will explain in detail proactive procedures that must be performed by the owner between scheduled service intervals in order to maintain the boat and engine in top shape all the time, thus reducing the 75% failure rate to a merely few percent attributed mostly to bad luck. Because let’s be honest here, if we are allowed to have a bad day now and then so is our boat!

Rares Badrea

Senior Marine Technician